Akụkụ Titanium alloy Tractor Part/Metal Sand Machinery/Machined Steel/Mechanical/Motor Parts for Compressor Ahụ

| Ihe onwunwe | Aluminom: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| igwe anaghị agba nchara: SS201, SS301, SS303, SS304, SS316, SS430 wdg | |

| Steel: nwayọọ ígwè / carbon ígwè gụnyere 1010, 1020, 1045, 1050, Q690 wdg | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 wdg. | |

| Ọla kọpa: C11000, C12000, C12000, C17200, C72900, C36000 wdg. | |

| Nhazi | Germany Trumpf ika Laser cutter, igwe ịkwa akwa CNC, igwe na-ehulata CNC, |

| (CNC) igwe stamping, igwe eji agbado ọkụ, igwe ịgbado ọkụ dị iche iche, CNC igwe etiti. | |

| Elu | Aluminom: Anodization, Sandblast, brushing, Polishing, Electro-plating etc |

| Igwe anaghị agba nchara: Nchacha, ịhịa aka n'ahụ, Passivating, Sandblasting, Electro-plating | |

| Steel: Zinc plating, Nickel plating, Chrome plating, Powder mkpuchi, eserese wdg | |

| Brass & ọla kọpa: ịsa ahịhịa, polishing wdg | |

| Nkenkenke | + 0.1mm |

| Ngwa | Ụgbọ okporo ígwè, ụgbọ ala, ụgbọala, ahụike, igwe, akụrụngwa, eletriki, eletriki wdg |

Titanium bụ ụdị ọla ọhụrụ.Ọrụ nke titanium metụtara ọdịnaya nke adịghị ọcha dị ka carbon, nitrogen, hydrogen na oxygen.Ọdịnaya nke adịghị ọcha na titanium iodide dị ọcha bụ ihe na-erughị 0.1%, ma ike ya dị ala na plasticity dị elu. Ihe onwunwe nke 99.5% ụlọ ọrụ mmepụta ihe dị ọcha titanium bụ ndị a: njupụta ρ = 4.5g / cm3, agbaze 1725 ℃, conductivity thermal λ = 15.24W / (mK), ike ike σb = 539MPa, elongation δ = 25%, akụkụ shrinkage ψ = 25%, modul nke elasticity E = 1.078 × 105MPa, ike HB195.

Ike dị elu

The njupụta nke titanium alloy bụ n'ozuzu banyere 4.51g / cm3, naanị 60% nke ígwè, na ụfọdụ elu ike titanium alloys gafere ike nke ọtụtụ alloy structural steels. Ya mere, kpọmkwem ike (ike / njupụta) nke titanium alloy bụ nnọọ ukwuu. karịa nke ndị ọzọ metal structural ihe, nke nwere ike na-emepụta akụkụ na elu unit ike, ezi rigidity na ìhè arọ.Aircraft engine components, skeleton, akpụkpọ, fasteners na ọdịda gia niile na-eji titanium alloy.

Ike thermal dị elu

The ojiji okpomọkụ bụ narị ole na ole degrees elu karịa aluminum alloy, ka nwere ike ịnọgide na-enwe ike chọrọ na ọkara okpomọkụ, nwere ike na-arụ ọrụ ruo ogologo oge na 450 ~ 500 ℃ okpomọkụ.Ndị a ụdị abụọ nke titanium alloy na 150 ℃ ~ 500 ℃ nso ka nwere nnọọ elu kpọmkwem ike, na aluminum alloy na 150 ℃ kpọmkwem ike ebelata significantly.The na-arụ ọrụ okpomọkụ nke titanium alloy nwere ike iru 500 ℃, mgbe nke aluminum alloy bụ n'okpuru. 200 ℃.

Ezigbo iguzogide corrosion

Nguzogide corrosion nke titanium alloy dị mma karịa nke igwe anaghị agba nchara na ikuku mmiri na mmiri mmiri.Pitting corrosion, acid corrosion, stress corrosion resistance bụ karịsịa ike; Ọ nwere magburu onwe corrosion iguzogide alkali, chloride, chlorine organic ngwaahịa, nitric acid. , sulfuric acid, wdg. Ma nguzogide corrosion nke titanium iji belata ikuku oxygen na chromium adịghị mma.

Ọmarịcha arụmọrụ dị ala

Titanium alloy nwere ike ịnọgide na-enwe ya n'ibu Njirimara na ala na ultra-ala okpomọkụ.Titanium alloys na ezi ala okpomọkụ arụmọrụ na nnọọ ala interstitial ọcha, dị ka TA7, nwere ike ịnọgide na-enwe a ụfọdụ plasticity na -253 ℃.Ya mere, titanium alloy bụkwa ihe dị mkpa. obere okpomọkụ ihe nhazi.

Ọrụ kemịkal dị elu

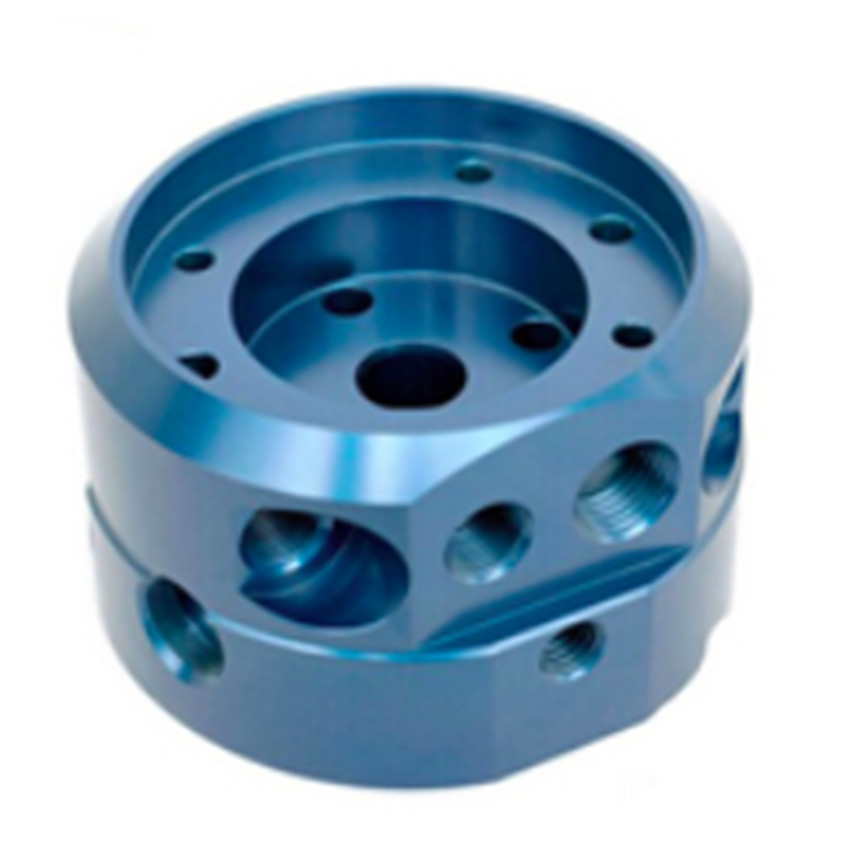

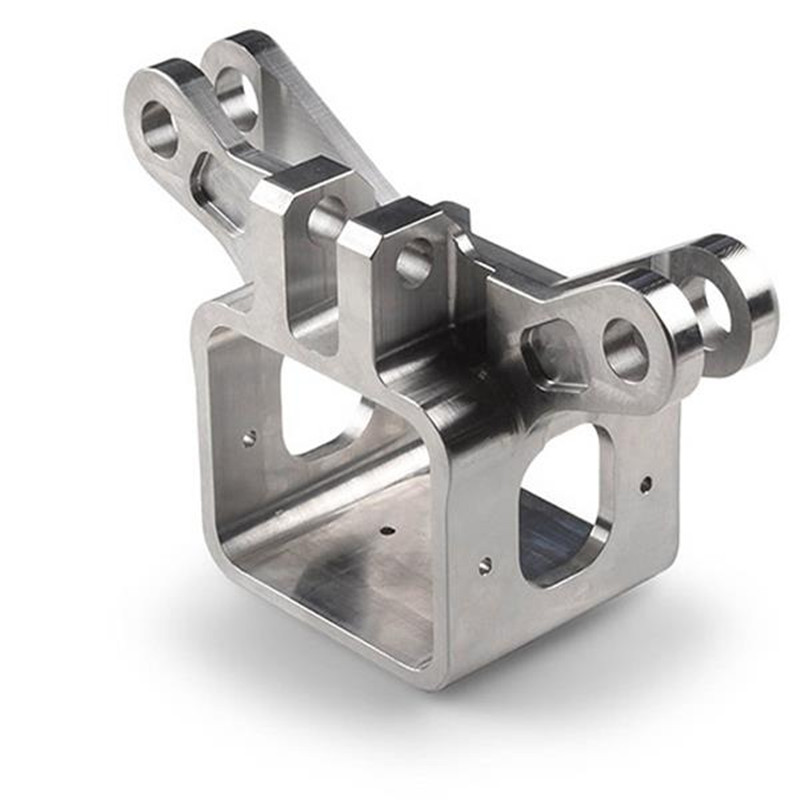

Ngwaahịa Titanium alloy

Ngwaahịa Titanium alloy

Titanium nwere mmeghachi omume kemịkalụ siri ike na O2, N2, H2, CO, CO2, vapor water, amonia na gas ndị ọzọ na ikuku. Mgbe ọdịnaya carbon karịrị 0.2%, a ga-emepụta TiC siri ike na alloy titanium. okpomọkụ dị elu, a ga-emepụta akwa akwa akwa TiN siri ike site na mmekọrịta ya na N.Mgbe okpomọkụ dị n'elu 600 ℃, titanium na-amịkọrọ oxygen ma mepụta oyi akwa siri ike na nnukwu hardness. Dị ka ihe hydrogen na-ebili, oyi akwa ga-agbaji. na-etolitekwa.The omimi nke ike na kenkuwa elu oyi akwa na-emepụta site absorption nke gas nwere ike iru 0.1 ~ 0.15 mm, na hardening ogo bụ 20% ~ 30%.Titanium chemical affinity bụkwa nnukwu, dị mfe ịmepụta adhesion na esemokwu. elu.

Obere elasticity thermal conductivity

Thermal conductivity nke titanium (λ = 15.24W / (m·K)) bụ ihe dị ka 1/4 nke nickel, 1/5 nke ígwè, 1/14 nke aluminum, na thermal conductivity nke titanium dị iche iche. Alloys dị ihe dị ka 50% dị ala karịa nke titanium. Ihe na-agbanwe agbanwe nke titanium alloy bụ ihe dịka 1/2 nke ígwè, ya mere nkwụsi ike ya adịghị mma, dị mfe nrụrụ, ekwesịghị ịbụ nke mkpara dị gịrịgịrị na akụkụ ndị nwere mgbidi dị mkpa, na-egbutu mgbe. nhazi nke elu nke nlọghachi azụ buru ibu, ihe dị ka 2 ~ 3 ugboro nke igwe anaghị agba nchara, na-akpata esemokwu siri ike, nchikota, nrapado na-eyi n'elu ngwá ọrụ.