Ngwaahịa

-

Nkedo ọla kọpa flange

ngosi ngwaahịa:

Flange a na-akpọkwa flange ma ọ bụ flange. Akụkụ nke na-ejikọta ọkpọkọ na ọkpọkọ, jikọtara ya na njedebe ọkpọkọ. Enwere oghere na flange na bolts na-ejikọta flanges abụọ ọnụ.Gasket n'etiti flanges.Flange bụ ụdị diski, na Injinia pipeline a na-ejikarị, flanges na-eji ụzọ abụọ. N'ime injinia ọkpọkọ, a na-ejikarị flanges maka njikọ ọkpọkọ. Wụnye otu flange na njedebe ọ bụla nke ọkpọkọ abụọ ahụ.Enwere ike ijikọ ọkpọkọ ndị dị ala na flange waya.A na-eji flange ịgbado ọkụ maka nrụgide nke ihe karịrị 4kg.Ebe a gasket n'etiti flanges abụọ ahụ ma kpochie ha.

Flanges nke nrụgide dị iche iche nwere nha dị iche iche ma jiri bolts dị iche iche.

Pumps na valves, mgbe ejikọtara ya na ọkpọkọ, a na-emekwa akụkụ nke akụrụngwa ndị a n'ụdị flange kwekọrọ, nke a makwaara dị ka njikọ flange.

General na abụọ ụgbọ elu na mpụta nke ojiji nke bolts na mechiri emechi akụkụ njikọ, na-akpọkarị "flange", dị ka ventilashion ọkpọkọ njikọ, ụdị akụkụ nwere ike na-akpọ "flange akụkụ".

Eriri flange bụ ụdị flange.The threaded flange njikọ Ọdịdị bụ mgbakọ, nke na-emi esịnede a ụzọ flanges, ọtụtụ bolts, akụ na gasket.

Okwu mmalite:

1/2 "--30" eriri flange

Ụkpụrụ ndị China:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

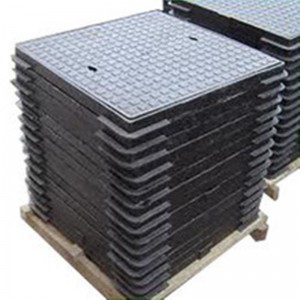

Mkpuchi oghere

ngosi ngwaahịa:

Ezi ike siri ike. Uru mmetụta dị ka nke ọkara carbon ígwè, nke bụ ihe karịrị 10 ugboro nke isi awọ isi awọ.

Nguzogide corrosion siri ike.Na nyocha mmiri na-agba mmiri, ọnụọgụ corrosion na ụbọchị 90 bụ naanị 1/40 nke ọkpọkọ ígwè na 1/10 nke ọkpọkọ isi awọ. Ndụ ọrụ bụ oge 2 nke ọkpọkọ isi awọ na 5. ugboro nkịtị ígwè ọkpọkọ.

Ezi plasticity.Elongation ≥7%, yiri elu carbon ígwè, ma isi awọ ígwè ihe elongation bụ efu.

High energy.The tensile ike ob ≥420MPa na ike ike OS ≥300MPa bụ otu ihe ahụ dị ka obere carbon ígwè na ugboro atọ dị ka isi awọ ígwè ihe.

N'ihi na ya nodular graphite microstructure, ductile ígwè dị mma karịa nkedo ígwè na mbenata ikike ịma jijiji, ya mere, ọ bara uru ka ibelata nrụgide.Ihe dị mkpa mere ị na-ahọrọ ductile ígwè bụ na ductile ígwè na-eri ihe na-erughị nkedo ígwè.The ọnụ ala nke ductile. ígwè na-eme ka ihe a na-ewu ewu na-ewu ewu, na-arụ ọrụ nke ọma na nke na-abaghị uru maka igwe.

The ike nke ductile ígwè bụ tụnyere nke nkedo steel.Ductile ígwè nwere elu mkpụrụ ike, na a kacha nta mkpụrụ ike nke 40K na nkedo ígwè mkpụrụ ike nke naanị 36K.Ductile ígwè bụ ihe na-eguzogide ọgwụ corrosion na oxidation karịa nkedo ígwè na. ọtụtụ ngwa ime obodo dị ka mmiri, mmiri nnu, uzuoku, wdg.

-

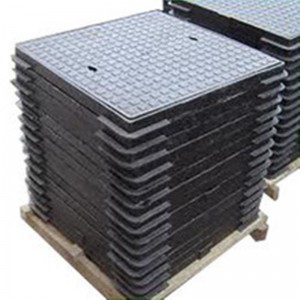

Ihe mkpuchi ihe nkedo ígwè

ngosi ngwaahịa:

Ezi ike siri ike. Uru mmetụta dị ka nke ọkara carbon ígwè, nke bụ ihe karịrị 10 ugboro nke isi awọ isi awọ.

Nguzogide corrosion siri ike.Na nyocha mmiri na-agba mmiri, ọnụọgụ corrosion na ụbọchị 90 bụ naanị 1/40 nke ọkpọkọ ígwè na 1/10 nke ọkpọkọ isi awọ. Ndụ ọrụ bụ oge 2 nke ọkpọkọ isi awọ na 5. ugboro nkịtị ígwè ọkpọkọ.

Ezi plasticity.Elongation ≥7%, yiri elu carbon ígwè, ma isi awọ ígwè ihe elongation bụ efu.

High energy.The tensile ike ob ≥420MPa na ike ike OS ≥300MPa bụ otu ihe ahụ dị ka obere carbon ígwè na ugboro atọ dị ka isi awọ ígwè ihe.

N'ihi na ya nodular graphite microstructure, ductile ígwè dị mma karịa nkedo ígwè na mbenata ikike ịma jijiji, ya mere, ọ bara uru ka ibelata nrụgide.Ihe dị mkpa mere ị na-ahọrọ ductile ígwè bụ na ductile ígwè na-eri ihe na-erughị nkedo ígwè.The ọnụ ala nke ductile. ígwè na-eme ka ihe a na-ewu ewu na-ewu ewu, na-arụ ọrụ nke ọma na nke na-abaghị uru maka igwe.

The ike nke ductile ígwè bụ tụnyere nke nkedo steel.Ductile ígwè nwere elu mkpụrụ ike, na a kacha nta mkpụrụ ike nke 40K na nkedo ígwè mkpụrụ ike nke naanị 36K.Ductile ígwè bụ ihe na-eguzogide ọgwụ corrosion na oxidation karịa nkedo ígwè na. ọtụtụ ngwa ime obodo dị ka mmiri, mmiri nnu, uzuoku, wdg.

-

Omenala grates

ngosi ngwaahịa:

Grizzley grates bụ otu ihe nkedo ígwè a na-eji ekpuchi grits, olulu na ihe nchebe ndị ọzọ na-echebe nchekwa mmadụ ma ọ bụ chebe osisi na ihe nchebe ndị ọzọ na mmebi.

Ngwongwo ndị ahụ bụ mmiri mmiri ozuzo, osisi osisi, grate grate, gratings ala, wdg. Dị ka ihe atụ, a na-etinyekarị ígwè ígwè n'ime mmiri mmiri nke ụlọ ịsa ahụ, na-ekwe ka mmiri na-abanye ma na-egbochi mmerụ ụkwụ na ụkwụ.

-

Resin na-ekpuchi

ngosi ngwaahịa:

1. Strong mgbochi-ezu ohi arụmọrụ: resin mejupụtara ihe manhole mkpuchi iji unsaturated resin, iko eriri na ihe ndị ọzọ na mesikwuru ọkpụkpụ compounded site pụrụ iche mmepụta usoro, mgbe elu okpomọkụ na pịa maka a akpụ, ihe recycling uru, ọ na-esi nnọọ ike. wepụ ígwè ígwè (wepụ uru nke ígwè na-akwụ ụgwọ karịa ígwè) ya mere ọ bụ ọrụ mgbochi na-arụ ọrụ.

2. Nnukwu ibu ikike: ala nke pụrụ iche ite ala Ọdịdị, nke mere na nrụgide ebe ụba ugboro iri ma ọ bụ ọbụna ọtụtụ ugboro.The na-aga n'ihu mkwado eriri na-eji iji hụ na eriri eriri na iko eriri ákwà na-integrated na ihe onwunwe, nke mere na ngwaahịa ahụ nwere ikike ibu zuru oke. na izute ma ọ bụ gafere ụkpụrụ mba.

3. Ogologo ọrụ ndụ, site na nnabata nke elu arụmọrụ resin, iko eriri na pụrụ iche usoro, mmepụta usoro iji hụ na penetration nke resins na iko eriri, ukwuu enwekwukwa osisi ọsọ agba anọ, na-eme ka ihe n'okpuru cyclic loading, adịghị emepụta esịtidem. mmebi, ka iji hụ na ndụ ọrụ nke ngwaahịa, na ndị ọzọ resin mejupụtara manhole mkpuchi na otu uru.Tinye njedebe na drawbacks nke ogbenye adhesion.

4. Mara mma na nke bara uru, ọkwa dị elu: Dị ka mkpa nke ndị ahịa dị elu si dị, anyị nwere ike ịme LOGO dị mgbagwoju anya na agba dị iche iche n'otu mkpuchi mkpuchi nke manhole nke ahaziri onwe ya, nke mere na ụkpụrụ ahụ dị nro, agba na-egbuke egbuke, iche.Na ike mere dị ka ndị ahịa ina na ụdị nile nke nkume pavement otu iṅomi nkume elu na agba.

5. Igwe ọkụ dị elu / dị ala, ihe mkpuchi dị mma na nkwụsị nke siri ike: nkwụsị nke corrosion, nke na-adịghị egbu egbu na nke na-adịghị njọ. Ọ dịghị ihe mgbakwunye metal, na-egwuri egwu n'ezie mmetụta mkpuchi mkpuchi. Enwere ike iji ya mee ihe na mgbagwoju anya, mgbanwe, siri ike na ebe na-achọsi ike. A nwalere ngwaahịa a site na ụlọ ọrụ nyocha ikike mba dị mkpa, yana acid doro anya na nguzogide alkali, nguzogide corrosion, mgbochi ịka nká na ihe ngosi ndị ọzọ eruola ma gafere ụkpụrụ mba.

6. Nchekwa gburugburu ebe obibi, mgbochi skid, ụda dị ala: ngwaahịa ahụ agaghị amị amị, ọ dịghị mkpọtụ siri ike na ihe na-agbanwe agbanwe mgbe ụgbọ ala ahụ kwụsịrị. N'otu oge ahụ, n'ihi ịdị arọ nke ngwaahịa ahụ, mkpuchi, nkwụsị oche oche ziri ezi. , merie mkpuchi nyocha ndị ọzọ "ịwụ elu, stilt, ụda, nchụpụ" na nsogbu ndị ọzọ.

-

Flange omenala

ngosi ngwaahịa:

Flange a na-akpọkwa flange ma ọ bụ flange. Akụkụ nke na-ejikọta ọkpọkọ na ọkpọkọ, jikọtara ya na njedebe ọkpọkọ. Enwere oghere na flange na bolts na-ejikọta flanges abụọ ọnụ.Gasket n'etiti flanges.Flange bụ ụdị diski, na Injinia pipeline a na-ejikarị, flanges na-eji ụzọ abụọ. N'ime injinia ọkpọkọ, a na-ejikarị flanges maka njikọ ọkpọkọ. Wụnye otu flange na njedebe ọ bụla nke ọkpọkọ abụọ ahụ.Enwere ike ijikọ ọkpọkọ ndị dị ala na flange waya.A na-eji flange ịgbado ọkụ maka nrụgide nke ihe karịrị 4kg.Ebe a gasket n'etiti flanges abụọ ahụ ma kpochie ha.

Flanges nke nrụgide dị iche iche nwere nha dị iche iche ma jiri bolts dị iche iche.

Pumps na valves, mgbe ejikọtara ya na ọkpọkọ, a na-emekwa akụkụ nke akụrụngwa ndị a n'ụdị flange kwekọrọ, nke a makwaara dị ka njikọ flange.

General na abụọ ụgbọ elu na mpụta nke ojiji nke bolts na mechiri emechi akụkụ njikọ, na-akpọkarị "flange", dị ka ventilashion ọkpọkọ njikọ, ụdị akụkụ nwere ike na-akpọ "flange akụkụ".

Eriri flange bụ ụdị flange.The threaded flange njikọ Ọdịdị bụ mgbakọ, nke na-emi esịnede a ụzọ flanges, ọtụtụ bolts, akụ na gasket.

Okwu mmalite:

1/2 "--30" eriri flange

Ụkpụrụ ndị China:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Steel pipi flange

ngosi ngwaahịa:

Flange a na-akpọkwa flange ma ọ bụ flange. Akụkụ nke na-ejikọta ọkpọkọ na ọkpọkọ, jikọtara ya na njedebe ọkpọkọ. Enwere oghere na flange na bolts na-ejikọta flanges abụọ ọnụ.Gasket n'etiti flanges.Flange bụ ụdị diski, na Injinia pipeline a na-ejikarị, flanges na-eji ụzọ abụọ. N'ime injinia ọkpọkọ, a na-ejikarị flanges maka njikọ ọkpọkọ. Wụnye otu flange na njedebe ọ bụla nke ọkpọkọ abụọ ahụ.Enwere ike ijikọ ọkpọkọ ndị dị ala na flange waya.A na-eji flange ịgbado ọkụ maka nrụgide nke ihe karịrị 4kg.Ebe a gasket n'etiti flanges abụọ ahụ ma kpochie ha.

Flanges nke nrụgide dị iche iche nwere nha dị iche iche ma jiri bolts dị iche iche.

Pumps na valves, mgbe ejikọtara ya na ọkpọkọ, a na-emekwa akụkụ nke akụrụngwa ndị a n'ụdị flange kwekọrọ, nke a makwaara dị ka njikọ flange.

General na abụọ ụgbọ elu na mpụta nke ojiji nke bolts na mechiri emechi akụkụ njikọ, na-akpọkarị "flange", dị ka ventilashion ọkpọkọ njikọ, ụdị akụkụ nwere ike na-akpọ "flange akụkụ".

Eriri flange bụ ụdị flange.The threaded flange njikọ Ọdịdị bụ mgbakọ, nke na-emi esịnede a ụzọ flanges, ọtụtụ bolts, akụ na gasket.

Okwu mmalite:

1/2 "--30" eriri flange

Ụkpụrụ ndị China:

HG5051 ~ 5028-58, HG20592 ~ 20605-97, 20615 ~ 20326-97

HGJ44 ~ 68-91, SH3406-92, SH3406-96

Shj406-89, SHT501-97, SYJS3-1-1 ~ 5

JB81 ~ 86-59, JB/T81 ~ 86-94, JB577-64

Jb577-79, JB585-64, JB585-79

JB1157 ~ 1164-82, JB2208-80, JB4700 ~ 4707-92

Jb4721-92, DG0500 ~ 0528, 0612 ~ 0616

GD0500 ~ 0528, GB9112 ~ 9125-88, GB/T13402-92 -

Omenala adịgboroja akụkụ

ngosi ngwaahịa:

The forging igwe na-eji na-emepụta plastic deformation site na-arụsi ọrụ ike na metal oghere iji nweta forging na ụfọdụ n'ibu Njirimara, udi na size.Through na-aga n'ihu hammering nke ọkpọkọ kwesịrị ekwesị, mbụ segregation, porosity, porosity, slag na ndị ọzọ compaction na. bonding na ingot na-ọzọ kọmpat, na plastic na n'ibu Njirimara nke metal na-mma. Forging ọkpọkọ oyiyi akwa tumadi gụnyere forging flange, forging mbenata ọkpọkọ, forging tee, etc.The isi ihe nke adịgboroja ọkpọkọ oyiyi akwa bụ Q235, Q345, 16Mn. ,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, etc.With kwekọrọ ekwekọ forging oyiyi akwa bụ nkedo kwesịrị ekwesị, na n'ibu Njirimara nke nkedo n'okpuru forgings na otu ihe n'ibu Njirimara, nkedo ọkpọkọ oyiyi akwa metal agbaze n'ime. na-agbaso ihe achọrọ nke ụfọdụ mmiri mmiri ma wụsa ya n'ime ihe, mgbe ọ dị jụụ solidification, ndị mmadụ na-enweta ọdịdị a kara aka, nha na arụmọrụ nke akụkụ nkedo (ma ọ bụ bl).ank) usoro.[1]

-

Ịme ọkpọkọ ígwè

ngosi ngwaahịa:

The forging igwe na-eji na-emepụta plastic deformation site na-arụsi ọrụ ike na metal oghere iji nweta forging na ụfọdụ n'ibu Njirimara, udi na size.Through na-aga n'ihu hammering nke ọkpọkọ kwesịrị ekwesị, mbụ segregation, porosity, porosity, slag na ndị ọzọ compaction na. bonding na ingot na-ọzọ kọmpat, na plastic na n'ibu Njirimara nke metal na-mma. Forging ọkpọkọ oyiyi akwa tumadi gụnyere forging flange, forging mbenata ọkpọkọ, forging tee, etc.The isi ihe nke adịgboroja ọkpọkọ oyiyi akwa bụ Q235, Q345, 16Mn. ,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, etc.With kwekọrọ ekwekọ forging oyiyi akwa bụ nkedo kwesịrị ekwesị, na n'ibu Njirimara nke nkedo n'okpuru forgings na otu ihe n'ibu Njirimara, nkedo ọkpọkọ oyiyi akwa metal agbaze n'ime. na-agbaso ihe achọrọ nke ụfọdụ mmiri mmiri ma wụsa ya n'ime ihe, mgbe ọ dị jụụ solidification, ndị mmadụ na-enweta ọdịdị a kara aka, nha na arụmọrụ nke akụkụ nkedo (ma ọ bụ bl).ank) usoro.[1]